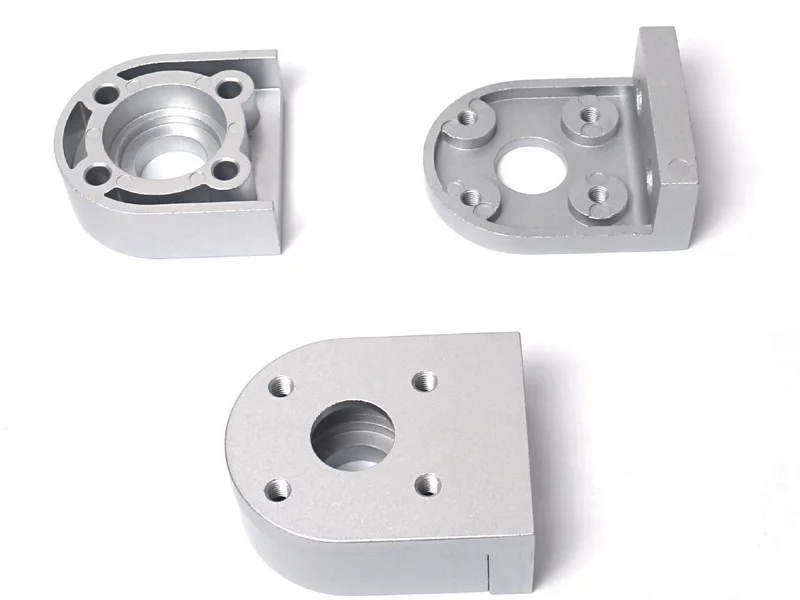

Aluminum Alloy Transmission Parts Bearing Seats

Aluminum alloy transmission parts bearing seat: the perfect combination of light weight and high performance

In modern mechanical equipment, the bearing seat is an indispensable core component. It supports the bearing, fixes the position of the shaft, and effectively reduces friction to ensure the smooth operation of the equipment. Today, we will introduce you in detail the Aluminum alloy transmission parts bearing seat from Westing. This product is made of high-quality aluminum alloy. With its lightweight, high strength and corrosion resistance, it has become an ideal choice for machinery manufacturing, automotive industry and aerospace. Let’s explore its unique advantages and wide applications together!

Product Introduction

Aluminum alloy transmission parts bearing seat is designed for high-precision mechanical equipment and is made of high-quality aluminum alloy materials. It has a compact structure and reasonable design, which can effectively support the bearing and reduce friction to ensure the efficient operation of the equipment. The product is precision-processed and has a smooth surface, which not only improves the aesthetics but also enhances durability.

- Material: High-strength aluminum alloy

- Color: Classic silver, full of modern sense

- Design: Compact structure, easy to install

- Packaging: Each set contains bearing seat and matching installation accessories

Material characteristics

Aluminum alloy is favored in industrial applications for its unique physical and chemical properties:

- Lightweight: The density of aluminum alloy is only 1/3 of that of steel, which significantly reduces the weight of equipment and improves overall efficiency.

- High strength: After special treatment, the strength of aluminum alloy is comparable to that of some steel, meeting high load requirements.

- Corrosion resistance: An oxide film is naturally formed on the surface of aluminum alloy, which effectively resists corrosion and prolongs service life.

- Excellent heat dissipation: Aluminum alloy has excellent thermal conductivity, which helps bearings dissipate heat quickly and reduce wear.

Design features

This aluminum alloy bearing seat is designed with full consideration of user needs and actual application scenarios:

- Precision machining: Advanced CNC technology is used to ensure accurate dimensions and seamless installation.

- Easy to install: Standard mounting holes are reserved, and only basic tools are needed to complete the assembly.

- Strong compatibility: Supports bearings of various specifications to meet the needs of different equipment.

- Beautiful and durable: Surface polishing improves visual effects and enhances wear resistance.

Application fields

Due to their excellent performance, aluminum alloy bearing seats are widely used in the following fields:

- Mechanical manufacturing: Used in machine tools, conveying equipment, etc. to ensure stable operation of equipment.

- Automotive industry: Provide reliable support in key parts such as engines and gearboxes.

- Aerospace: Lightweight characteristics make it an ideal choice for aircraft and spacecraft.

- Robotics: In high-precision robots, ensure the smooth operation of moving parts.

Installation method

Installing aluminum alloy bearing seats is simple and efficient, and can be completed in just a few steps:

- Prepare tools: Select a screwdriver or wrench according to the installation accessories.

- Position the bearing seat: Place the bearing seat in the predetermined position of the equipment to ensure alignment with the bearing.

- Fix the bearing seat: Use the matching screws to firmly fix the bearing seat, and pay attention to uniform strength.

- Check stability: After installation, check whether the bearing seat is firm and there is no looseness.

Product advantages

Compared with traditional steel bearing seats, aluminum alloy bearing seats have the following unique advantages:

- Lighter weight: Reduce the burden on equipment and improve operating efficiency.

- Better heat dissipation performance: Rapid heat dissipation, reduce bearing wear, and extend service life.

- Higher corrosion resistance: Adapt to a variety of environments and reduce maintenance costs.

- Environmental protection and energy saving: Aluminum alloy can be recycled and is in line with the concept of sustainable development.

Market comparison

There are many types of bearing seats on the market, but aluminum alloy bearing seats stand out with their comprehensive performance:

- Compared with steel bearing seats: Aluminum alloy bearing seats are lighter, have faster heat dissipation, and are more corrosion resistant.

- Compared with plastic bearing seats: Aluminum alloy bearing seats are stronger, more durable, and suitable for high-load scenarios.

- Compared with copper bearing seats: Aluminum alloy bearing seats are lower in cost, lighter in weight, and more widely used.

User evaluation

“This aluminum alloy bearing seat is of very good quality, easy to install, and the equipment runs more smoothly!” —— Mr. Wang, mechanical engineer

“This bearing seat is used in our robot project, with stable performance and excellent heat dissipation effect. Recommended!” —— Ms. Li, robotics expert

Conclusion

Whether you are a mechanical designer, automotive engineer, or a robotics enthusiast, this aluminum alloy transmission component bearing seat can provide you with excellent support. Its lightweight, high strength and corrosion resistance will bring higher efficiency and longer service life to your project. Take action now, buy this high-quality bearing seat, and start your innovation journey!

Keywords

Aluminum alloy bearing seat, transmission component, high-strength bearing seat, mechanical equipment accessories, automotive industry bearing seat, aerospace bearing seat, lightweight bearing seat, corrosion-resistant bearing seat

Aluminum alloy bearing seat, the perfect combination of lightweight and high performance!

High strength, corrosion resistance, easy installation, suitable for machinery, automobiles, aviation and other fields. Come and experience this high-quality transmission component!

Aluminum alloy bearing seat #Transmission component #Mechanical equipment #Automotive industry #Aerospace #Lightweight design

With this aluminum alloy transmission component bearing seat, you can easily achieve efficient operation and long-term durability of the equipment. Explore now and take your project to the next level!