CNC machined steel bolts, stud bolts with slots

Product Name

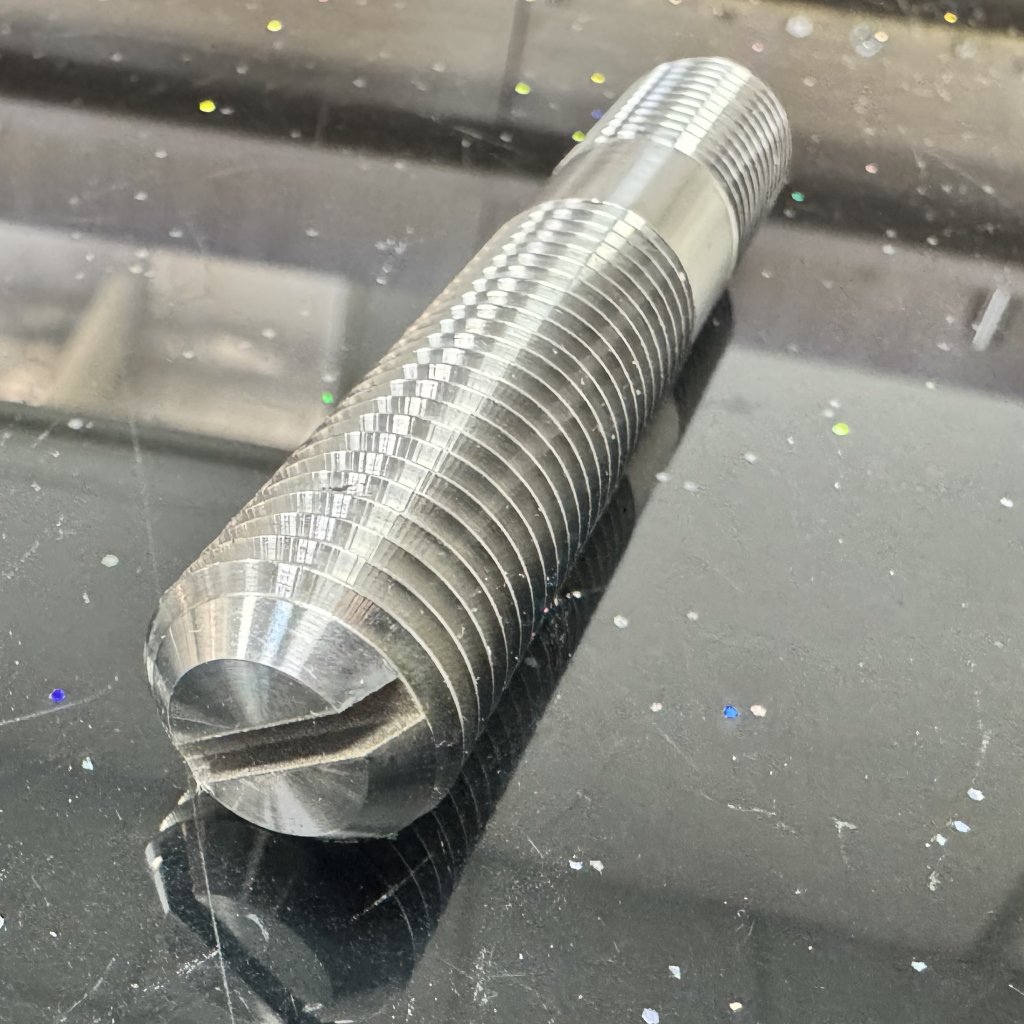

CNC Machined Steel Bolts and Studs with Slots

Product Description

CNC Machined Steel Bolts and Studs with Slots is a high-performance fastener designed for industrial equipment, machinery manufacturing and construction engineering. It uses advanced CNC (Computer Numerical Control) machining technology to ensure that the dimensional accuracy and thread quality of bolts and studs meet the highest standards. The product is made of high-strength steel with a special surface treatment for excellent corrosion resistance and fatigue resistance. The unique slot design not only facilitates installation and adjustment, but also provides additional stability in high-vibration environments. It is widely used in the automotive industry, steel structure buildings, mechanical equipment assembly and other scenarios.

Product Features

- High-precision manufacturing: CNC machining technology is used to ensure that the dimensional tolerance of bolts and studs is controlled within ±0.01mm, and the thread accuracy meets international standards.

- High-quality steel: High-strength steel (such as 42CrMo, 35CrMo) is selected, which is heat-treated with high hardness and strong tensile strength to adapt to harsh working environments.

- Slotted design: Slots are provided on the bolt head or both ends of the stud bolt, which is convenient for installation and adjustment using tools, reducing installation time and improving work efficiency.

- Corrosion-resistant surface: The surface is galvanized, hot-dip galvanized or Dacromet-treated, with strong corrosion resistance, suitable for outdoor and humid environments.

- Multiple specifications: A variety of thread specifications such as M6 to M36 are provided, and the length can be customized to meet the fastening requirements of different equipment and structures.

- Stud bolt characteristics: Both ends of the stud bolt are threaded, suitable for connecting two parts, and the slot design further enhances the flexibility of fixing and adjustment.

Product advantages

- High strength and durability: The steel material and heat treatment process ensure that the bolts and stud bolts can remain stable under high load and vibration environments, extending the service life.

- Easy to install: The groove design makes installation and disassembly easier, especially suitable for equipment that requires frequent adjustment or maintenance.

- Wide applicability: Applicable to a variety of fields such as machinery manufacturing, automobile industry, steel structure construction, bridge engineering, etc., to meet the fastening needs of different industries.

- Customized service: The thread specifications, length and groove depth can be customized according to customer needs to meet special application scenarios.

- Environmental protection and safety: The surface treatment process meets environmental protection standards to ensure the safe use of the product in various environments.

Technical parameters

| Parameter items | Specifications |

|---|---|

| Material | High-strength steel (such as 42CrMo, 35CrMo) |

| Surface treatment | Galvanized, hot-dip galvanized, Dacromet |

| Thread specifications | M6 to M36 (customizable) |

| Length | 20mm to 500mm (customizable) |

| Slot width | 2mm to 10mm (customizable) |

| Tensile strength | ≥1040MPa |

| Hardness | HRC28-35 |

| Working temperature | -40℃ to 200℃ |

Installation guide

- Select specifications: Select the appropriate bolt or stud bolt specifications according to the thickness and force requirements of the connected parts.

- Prepare tools: Use a wrench or special tool to match the slot design for easy installation and adjustment.

- Installation steps: Insert the bolt or stud into the pre-drilled hole, use the tool to rotate until it is tightened, and ensure that the slot is aligned with the installation position.

- Check tightening: After installation, check whether the bolt or stud is tightened in place and there is no looseness.

Application scenarios

- Mechanical equipment assembly: Used to fix mechanical parts to ensure stable operation of equipment under high-intensity working conditions.

- Automotive industry: Provide high-strength tightening in key parts such as automobile engines and chassis to enhance safety.

- Steel structure building: Used for the connection of steel beams and steel columns to ensure the stability and durability of the building structure.

- Bridge engineering: Provide reliable tightening solutions in the connection and support structure of the bridge.

Comparison with competitors

| Comparison items | CNC machined steel bolts and studs with grooves | Traditional bolts and studs |

|---|---|---|

| Manufacturing accuracy | CNC machining, high accuracy | Conventional machining, average accuracy |

| Ease of installation | Slotted design, easier installation and adjustment | Slotless design, time-consuming installation |

| Corrosion resistance | Multiple surface treatments available, strong corrosion resistance | Single surface treatment, easy to rust |

| Customization | Customizable specifications and groove depth | Fixed specifications, difficult to customize |

- CNC machined bolts

- Steel studs

- Slotted bolts

- High-strength fasteners

- Mechanical equipment bolts

- Automotive industry bolts

- Steel structure fasteners

- Corrosion-resistant bolts

Summary

Slotted CNC Machined Steel Bolts and Studs With its high-precision manufacturing, high-quality steel and innovative slotted design, it is an ideal choice in the field of industrial fastening. Whether it is mechanical equipment, automotive industry or steel structure construction, this product can provide efficient and durable fastening solutions. Through strict quality control and diversified customization services, we are committed to providing every user with a satisfactory product experience. If you are looking for a high-strength, easy-to-install and corrosion-resistant fastener, this slotted CNC machined steel bolt and stud is definitely worthy of your trust!

Steel stud bolts, if the quantity is small, will generally be made of round steel, cut, and then processed.

Measuring tools for product testing